Molybdenum in SteelOften referred to as moly by steelmakers and metallurgist, molybdenum is an impor

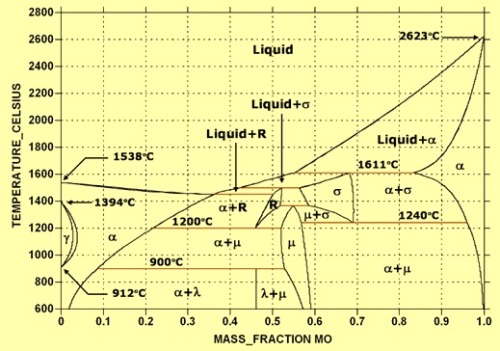

Molybdenum in SteelOften referred to as moly by steelmakers and metallurgist, molybdenum is an important alloying element in many steels, granting hardenability, corrosion resistance, and other favorable properties. Molybdenum is often mined in the form of molybdenite (MoS2) and added in the form of ferromolybdenum, molybdenum trioxide, or sometimes scrap. Molybdenum is a ferrite stabilizer, lowering the solubility of carbon in austenite, forming strong carbides, and decreasing the temperature range at which austenite exists. Less than 1% of the element in steel is needed to form these carbides that increase the strength and hardness of the resulting material, though in the presence of stronger carbide formers molybdenum carbides are less likely. Steels with molybdenum carbides can be used in high temperature environments and are resistant to hydrogen blistering.A strong hardenability agent, only about 0.5% molybdenum or less is added to heat treatable steels to increase their final strength and hardness. For heat treatable steels containing chromium, the addition of molybdenum can alleviate their susceptibility to temper embrittlement. In austenitic stainless steels, molybdenum helps increase corrosion and pitting resistance, notably in marine environments or against sulfuric acid. In martensitic stainless steels molybdenum increases pitting resistance, and in ferritic stainless steels it improves resistance to marine environments and some organic acids.Finally, up to 9% molybdenum can be added to certain tool steels, increasing hardness, wear resistance, and strength at elevated temperatures. The M-series of high speed steels, specifically, contain between 3.5-9.5% molybdenum.Sources/Further Reading: ( 1 ) ( 2 ) ( 3 - image 1 ) ( 4 ) ( 5 )Image sources: ( 2 ) ( 3 ) -- source link

Tumblr Blog : materialsscienceandengineering.tumblr.com

#materials science#science#molybdenum#alloys#mymsepost