Additive Manufacturing: Directed Energy DepositionA type of metal additive manufacturing process, di

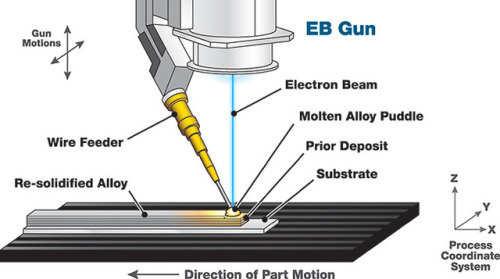

Additive Manufacturing: Directed Energy DepositionA type of metal additive manufacturing process, directed energy deposition (DED) uses either powders or wires to create finished parts. Unlike most other AM processes, DED is commonly used to repair components or add additional material, rather than simply create new parts.Types of directed energy deposition, or other names for the process, include directed metal deposition (DMD), laser metal deposition (LMD), laser-engineered net shaping (LENS), and laser consolidation (LC).DED uses a deposition head to feed either powder or wire into a laser (or electron) beam that melts the material, thereby building up the surface of the part. Because it is not melting material that has already been laid down (such as in powder bed fusion), DED can build on existing parts. Powders can also be mixed, utilizing different material properties. Using different, compatible materials can increase wear, corrosion, and oxidation resistance, one of the benefits of DED.Limited in size only by the beam manipulation system, another benefit is that DED can produce relatively large parts, as shown in the top right image above: Sciaky (a US 3D printing company) can make 5-meter-large parts in a variety of different materials. Because of the method of deposition, there is also little to no waste involved. However, DED is also a relatively slow process, which takes much longer than other methods to produce parts. Sources: ( 1 - image 1 ) ( 2 - image 3 ) ( 3 - images 2 and 4 ) ( 4 ) -- source link

Tumblr Blog : materialsscienceandengineering.tumblr.com

#materials science#science#additive manufacturing#3d printing#metals#powders#metal powders#mymsepost