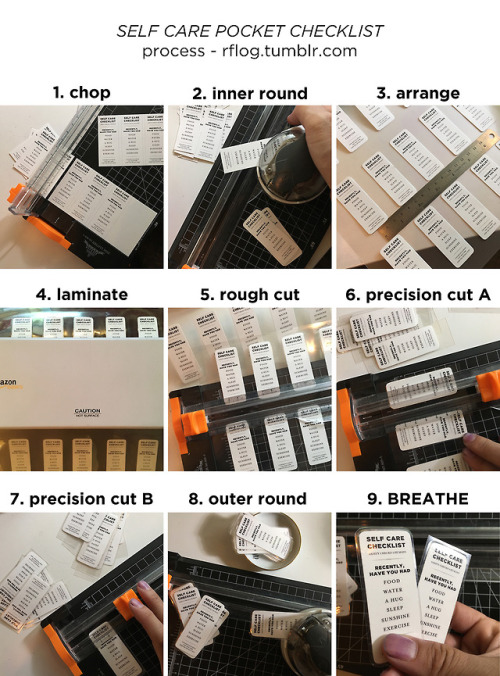

Had to regenerate a new batch of my self-care pocket checklists for an upcoming trip (we may ha

Had to regenerate a new batch of my self-care pocket checklists for an upcoming trip (we may have different definitions of necessity) and figured I might as well document why the details which may seem so natural in the end result are wildly unnatural to execute.Lamination film doesn’t just magically hold like magnets, of course – it’s gotta have a margin around the object it contains, so it can adhere to itself. But since you have to arrange objects in your lamination pouch by hand and then delicately lift the pouch into the machine, there will inevitably be some misalignment. So one pain about laminating many small objects is that you have to spend extra time cutting all their edges individually, and you can’t scale by cutting in a grid.This little Kadomaru corner cutter is my raddest (only?) papercutting investment other than the straight cutter. It cuts three incremental sizes of corners, which is perfect for cutting internal corners with one corner size and external laminate corners with the next size up. I do the same for my tiny A8 notebooks, cutting the cover corners to the next size larger than the page corners.(As usual, I attained this process by making everything up as I went along – there may well be a more efficient way that my future self will be kicking me for not realizing earlier. If so, please drop me a message.) -- source link

Tumblr Blog : rflog.tumblr.com

#process#detail#constraints#papercraft#self care#physical#design#graphic design#instructable